Alternative Energy

LEP, supported by Quadrant Plastics, has been a solution provider for the energy generation industry for many years.

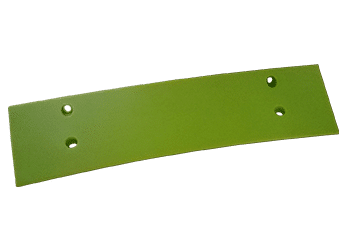

Our expertise is built on application successes in traditional energy sectors like oil & gas, but more and more in emerging alternative energy fields such as wind and solar.

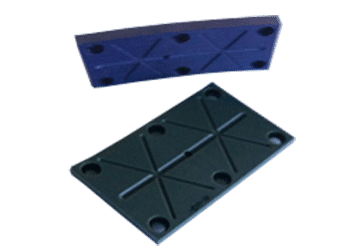

Our materials are extensively tested and able to operate under harsh chemical and even extreme thermal conditions.

Our high performance materials offer the advantages of all plastics, helping to reduce weight and allow for the substitution of other materials like steel, aluminium or ceramics, due to their high specific strength.

Solar: Our materials have been tested and certified for applications in vacuum chambers offering very low out gassing. We also offer materials for wet process environments presenting low out leach values.