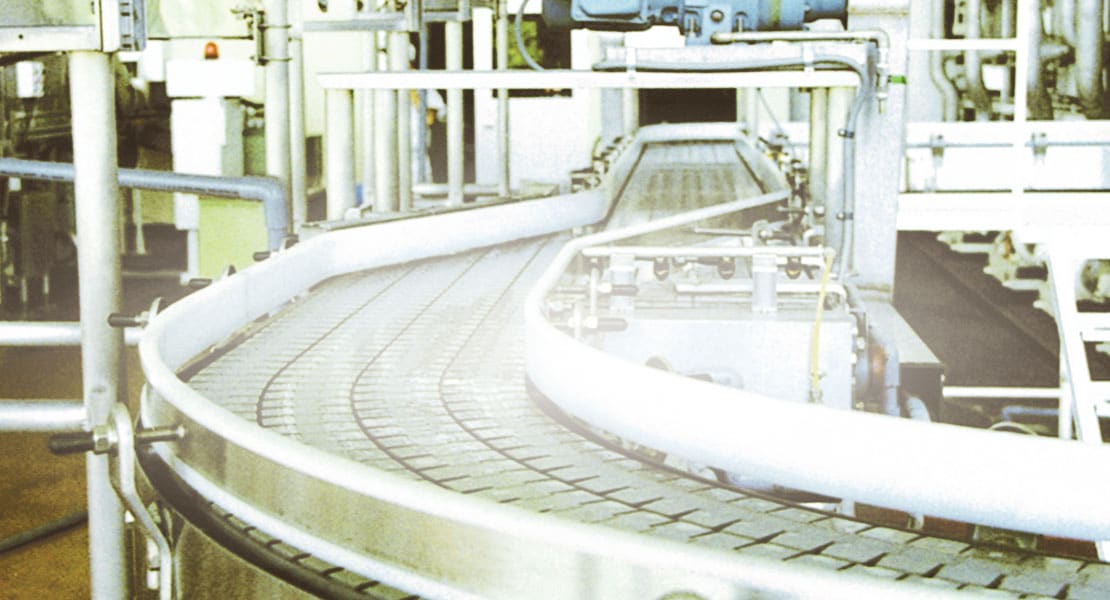

LEP specialises in providing solutions for the Industrial market. On any production line of any kind of equipment LEP solves problems or produces replacement parts, with the aim of keeping production lines running smoother, faster, longer or better – to ultimately increase our customer’s production efficiency and profitability.

Our extensive experience enables us to develop high performance solutions to critical applications and uses.

We custom engineer product solutions to meet your operating and performance parameters in any and every industrial environment, taking into account common factors such as abrasion, aggressive chemical media, speed, or temperature.

On every production line of any kind of equipment, LEP solves problems or proposes new materials, with the aim of keeping production lines running smoother, faster, longer and better – to ultimately increase our customer’s production efficiency profitability.

Materials |

Applications |

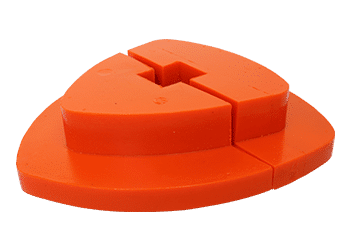

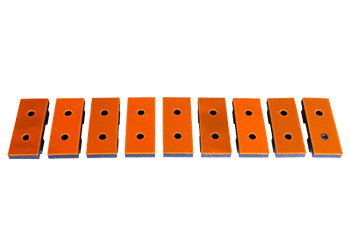

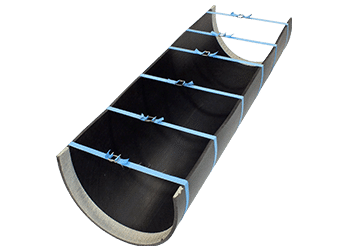

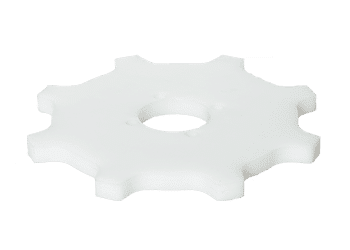

| Uhmwpe -BR | Underchain wear strips, guide rails, bearings, chutes, hopper linings, electrical insulation, gears/sprockets, bottling star wheels, food process machining, chemical handling |

| Nylon 6 | Electrical insulation, sheaves, rollers, gears/sprockets |

| Nylon LFX | Under chain wear strips, guide rails, bearings, piston rings |

| Acetal | Bearings, Electrical insulation, rollers, gears/sprockets, saw guides, food process machining |

| Polycarbonate | Machine guards, covers, housings and trims |

| Acrylic | Feed hoppers, machine guards |

| Polypropylene | Clicking boards, food process machining, chemical handling |

| PVC | Electrical installation, chemical handling |

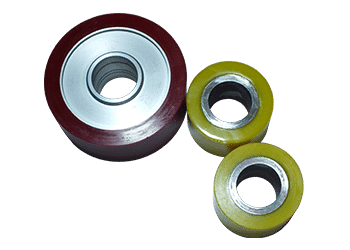

| Lurethane | Gears/sprockets, drive rollers |

| PTFE | Bearings, electrical insulation, piston rings, thermal insulation, clicking boards, chemical handling |

| PEEK | Bearings, sheaves, food process machining |

| Micarta | Bearings, electrical insulation, rollers, saw guides, heat sealing bars |